DOOLIM-YASKAWA

- Painting

Solution-

DOOLIM-YASKAWA

Customized painting process

Automatic Painting

Solution

- Painting Automation

- Painting Process

- Painting Quality Inspection

- Vision System

- Painting Software

- Paint Circulation System

-

- Automation

Solution-

DOOLIM-YASKAWA

Innovation in manufacturing

Automatic Robot

Solution

- Sealing Automation

- Bonding Automation

- Sanding Automation

- Assembly Automation

- Cleaning Automation

- Transfer & Palletizing

-

- Engineering

Service-

DOOLIM-YASKAWA

For customers satisfaction

Engineering Service

- R&D

- Engineering

- Customer Service

- Training Center

- Case Studies

- Document

-

- Media

-

Delivering

The Latest News

- News Room

- Social Media

-

- About Us

-

- Solution Component

- Robot Applicator System Device

- Painting

Solution - Automation

Solution - Engineering

Service - Media

- About Us

-

- Solution Component

- Robot Applicator System Device

Painting Software

We offer optimized automation solutions through our proprietary software development.

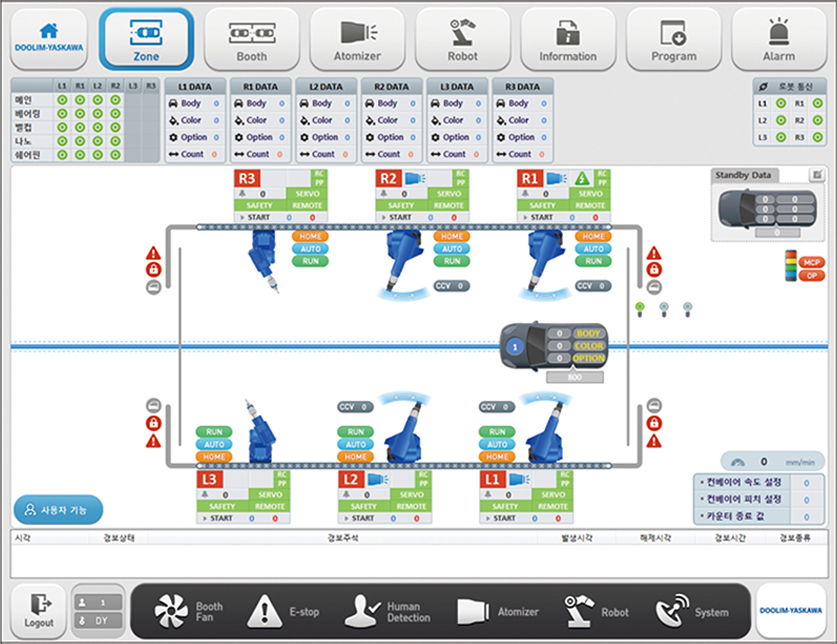

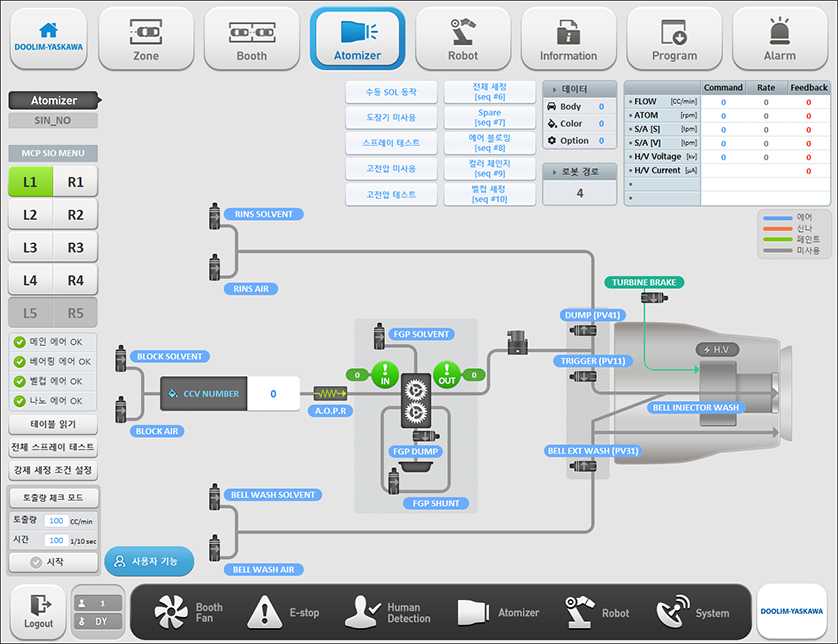

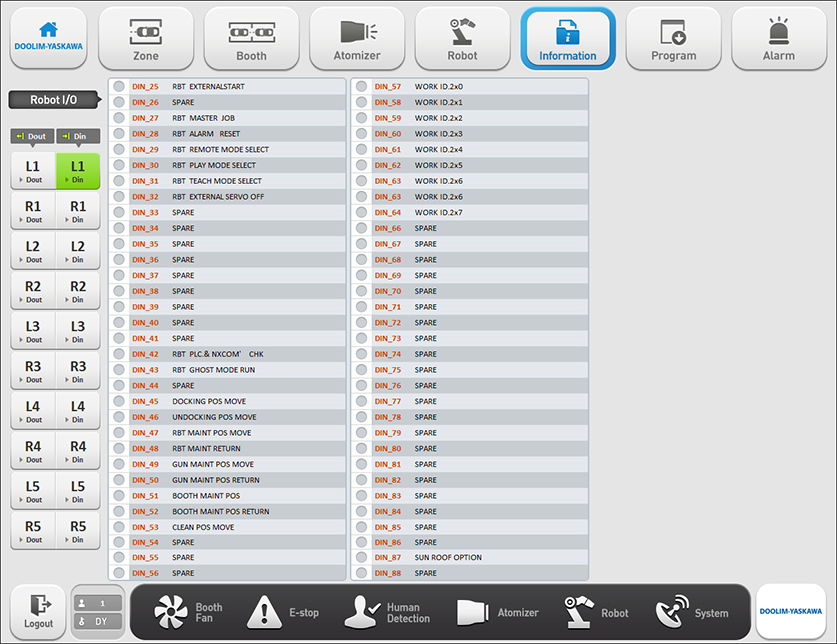

Mate.D HMI

Mate.D HMI provides a function for systematic management of production processes. It enables real-time monitoring of painting and sealing processes such as zones, booths, and pottery, allows control of the robot and the atomizer.

Features

| Easy Control of Robots and Painting Component |

Functions

| Robot / Zone Monitoring | - Monitor the status of painting and sealing booths in real-time and control robots and painting modules. |

| Automizer Monitoring | - Monitor of air pressure status in painting equipment, flow rate checking, and real-time output of historical data are possible. |

| Monitoring of I/O status | - Monitor Fieldbus management and robot I/O system status in real-time. |

Installation Requirements

| Category | Installation Requirements | |

|---|---|---|

| OS | Windows 7, 64bit | |

| CPU | i5 and more | |

| Memory | 4 GB more | |

| Hard Disk | 500 GB more | |

| Graphic / Monitor | VGA / SVGA / XGA | |

| keyboard | 101 Key | |

| Mouse | Window Support Mouse | |

| Printer | Window Support Printer | |

| Serial Port | 2 USB2.0 Port | |

| Optimal Resolution | default | 1280*1024 |

| wide | 1920*1080 | |