DOOLIM-YASKAWA

- Painting

Solution-

DOOLIM-YASKAWA

Customized painting process

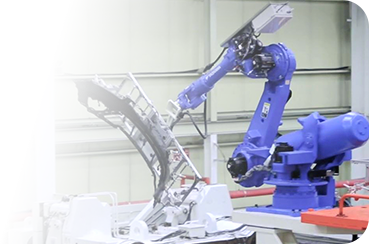

Automatic Painting

Solution

- Painting Automation

- Painting Process

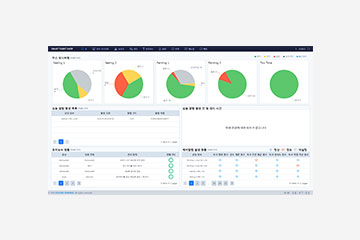

- Painting Quality Inspection

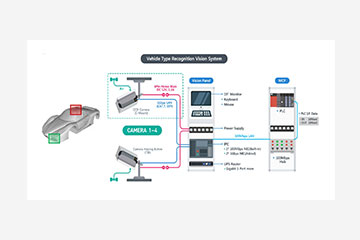

- Vision System

- Painting Software

- Paint Circulation System

-

- Automation

Solution-

DOOLIM-YASKAWA

Innovation in manufacturing

Automatic Robot

Solution

- Sealing Automation

- Bonding Automation

- Sanding Automation

- Assembly Automation

- Cleaning Automation

- Transfer & Palletizing

-

- Engineering

Service-

DOOLIM-YASKAWA

For customers satisfaction

Engineering Service

- R&D

- Engineering

- Customer Service

- Training Center

- Case Studies

- Document

-

- Media

-

Delivering

The Latest News

- News Room

- Social Media

-

- About Us

-

- Solution Component

- Robot Applicator System Device

- Painting

Solution - Automation

Solution - Engineering

Service - Media

- About Us

-

- Solution Component

- Robot Applicator System Device

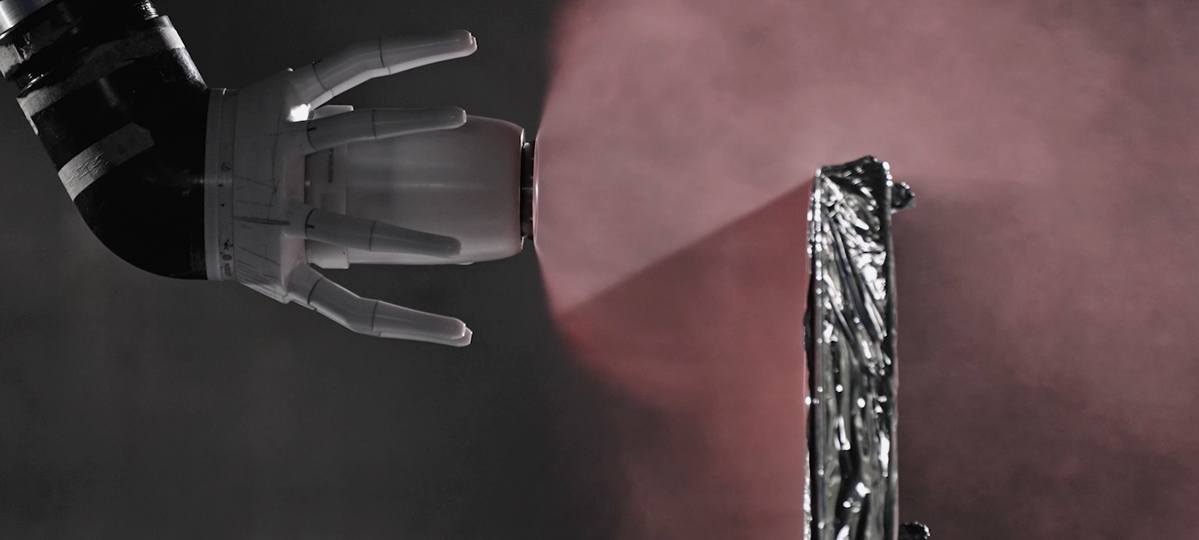

Painting Robot Solution

We implement high-quality painting finishes

through robotic painting automation solutions.

The painting process is a crucial step in product manufacturing, essential for delivering the highest quality and appearance.

We provide painting automation solutions tailored to each industry, enabling efficient production across various industrial sectors.

Manual verse Robotic Automation

- Manual Painting

-

vs

- Robotic Automation

-

Possible worker safety risks

- Safety

-

Ensuring worker safety

-

Difficulty achieving consistent quality

- Quality

-

Ensuring consistent quality

-

Increased time depending on worker skill level

- Production time

-

Reducing production time

-

Incurrence of labor costs

- Operating costs

-

Minimization of labor costs

-

Downtime occurs due to worker rest periods, holidays

- Productivity

-

High productivity with 24/7 operation

-

Difficulty in quickly implementation of changes

- Flexibility

-

Rapid implementation of changes

3-Step of painting

Benefits

Reduce commissioning time with pre-painting tests

Our customers can reduce their installation and

Reduce commissioning time with pre-painting tests

Our customers can reduce their installation andsetup time significantly by evaluating simulated

results in advance in our test facilities.

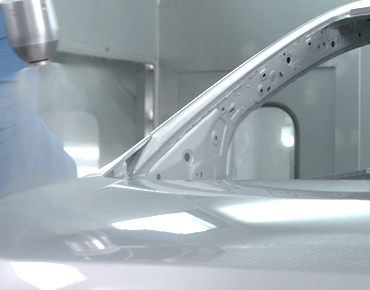

Have various painting equipment

The painting bell test unit we have is designed

Have various painting equipment

The painting bell test unit we have is designedto distinguish the painting quality of various

equipment, allowing customers to economically

test different options quickly.

Vehicle Manufacturing

Vehicle Manufacturing

Automotive Wheel

Automotive Wheel

Automotive Plastic Parts

Automotive Plastic Parts

Electronics

Electronics