DOOLIM-YASKAWA

- Painting

Solution-

DOOLIM-YASKAWA

Customized painting process

Automatic Painting

Solution

- Painting Automation

- Painting Process

- Painting Quality Inspection

- Vision System

- Painting Software

- Paint Circulation System

-

- Automation

Solution-

DOOLIM-YASKAWA

Innovation in manufacturing

Automatic Robot

Solution

- Sealing Automation

- Bonding Automation

- Sanding Automation

- Assembly Automation

- Cleaning Automation

- Transfer & Palletizing

-

- Engineering

Service-

DOOLIM-YASKAWA

For customers satisfaction

Engineering Service

- R&D

- Engineering

- Customer Service

- Training Center

- Case Studies

- Document

-

- Media

-

Delivering

The Latest News

- News Room

- Social Media

-

- About Us

-

- Solution Component

- Robot Applicator System Device

- Painting

Solution - Automation

Solution - Engineering

Service - Media

- About Us

-

- Solution Component

- Robot Applicator System Device

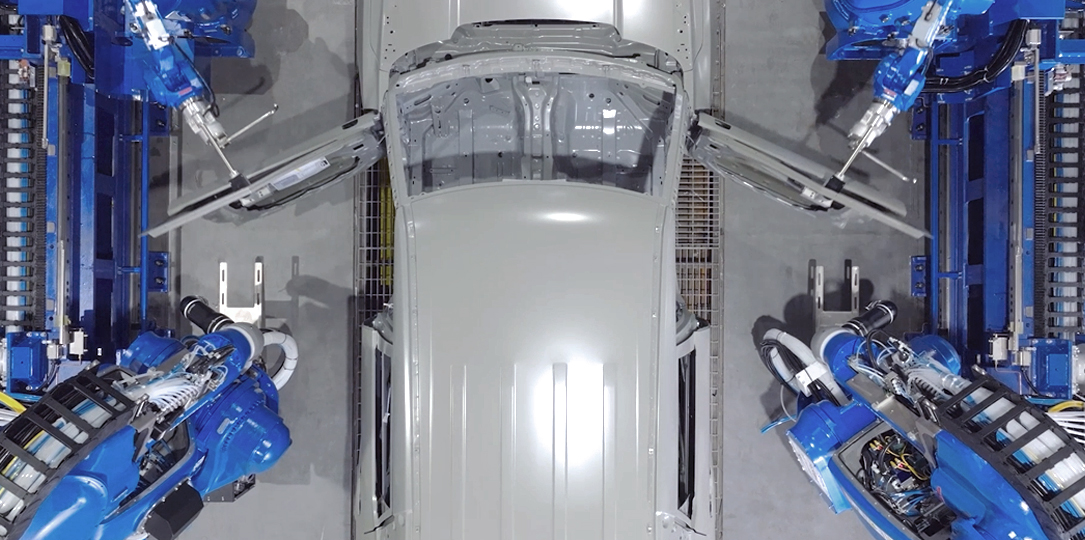

Painting Automation Process

We enhance the value of your product with our robotic painting automation solution.

Painting

Process

The painting automation process is divided into the internal painting process for the interior of the

body and the exterior painting process for the exterior. Our custom automation processes suit

customer product characteristics and manufacturing environments.

Painting Process

Multi-Painting

Process DOOLIM-YASKAWA offers a Multi-Painting Process that integrates interior and exterior painting

processes to minimize costs.

Process DOOLIM-YASKAWA offers a Multi-Painting Process that integrates interior and exterior painting

processes to minimize costs.

-

Exterior Painting This process is the last affecting the aesthetics of the automobiles, such as colors,

Exterior Painting This process is the last affecting the aesthetics of the automobiles, such as colors,

gloss, smoothness, and hatch and maintains durability by protecting the colors from

external conditions, including ultraviolet rays, oxygen, water, and heat. -

Interior Painting This is the process by which the robot applies paint to several areas of the inside door.

Interior Painting This is the process by which the robot applies paint to several areas of the inside door.

Interior painting requires an opener robot to open doors and the hood and tailgate

as well as an automated guided vehicle and painting robot.

· Applicable Products : Automobiles, Aerospace, Home Appliances, etc.

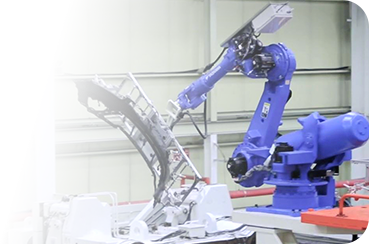

Opener Robot

For internal painting of products with doors, equipmentincludes attaching an opener to a robotic arm to automate

the opening and closing of doors.

Tracking Cart

By installing a conveyor system in the painting process,we can build an optimal production line suitable for

mass production of various models in narrow spaces.

Benefit of the Multi-Painting Process

shortened production lines.

of carbon emissions and other pollutants.