DOOLIM-YASKAWA

- Painting

Solution-

DOOLIM-YASKAWA

Customized painting process

Automatic Painting

Solution

- Painting Automation

- Painting Process

- Painting Quality Inspection

- Vision System

- Painting Software

- Paint Circulation System

-

- Automation

Solution-

DOOLIM-YASKAWA

Innovation in manufacturing

Automatic Robot

Solution

- Sealing Automation

- Bonding Automation

- Sanding Automation

- Assembly Automation

- Cleaning Automation

- Transfer & Palletizing

-

- Engineering

Service-

DOOLIM-YASKAWA

For customers satisfaction

Engineering Service

- R&D

- Engineering

- Customer Service

- Training Center

- Case Studies

- Document

-

- Media

-

Delivering

The Latest News

- News Room

- Social Media

-

- About Us

-

- Solution Component

- Robot Applicator System Device

- Painting

Solution - Automation

Solution - Engineering

Service - Media

- About Us

-

- Solution Component

- Robot Applicator System Device

Painting Quality Inspection

We provide quality stability through pre-painting quality tests.

Painting Quality

Inspection

DOOLIM-YASKAWA has a painting test lab for extensive tests in conditions like actual fields to find

the right painting quality for clients' products. This validates pre-painting quality pre-delivery,

offering tailored results.

Painting Test Lab

Painting Test Lab

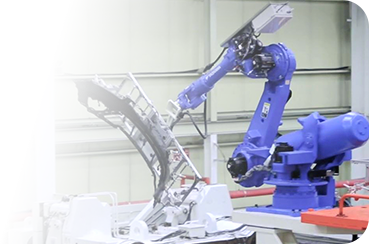

DOOLIM-YASKAWA’s painting test lab is designed to fully understand and optimize our clients' painting processes.

In this lab, we conduct tests on coatings, painting equipment, and perform quality inspections such as

paint thickness and color difference assessments.

In this lab, we conduct tests on coatings, painting equipment, and perform quality inspections such as

paint thickness and color difference assessments.

-

Painting Quality Inspection

Quality stabilization through quality inspectionTo ensure top quality before installation, we conduct tests including

paint thickness measurement, color difference inspection, and defect

analysis. After passing these tests, we deliver stable painting quality

to our clients. -

Coating and Painting Components Tests

Optimized design through preliminary component testing

We test coatings, machines, and components, assessing viscosity, parameters,

and patterns. By optimizing equipment for customer environments and product

characteristics, we achieve high-quality painting automation.

PaintIn the test lab, we can conduct paint tests for

PaintIn the test lab, we can conduct paint tests forPaint Test

each brand. We visually confirm the final

quality. Bell & Painting Component

Bell & Painting ComponentBell and Painting Components Test

In our test lab, we test electrostatic / non-

electrostatic bell and painting components to

verify and adjust parameters and patterns.

Benefits

through tests on equipment and coatings in real

field conditions, including film thickness

measurement and color difference inspection.

and addressing them, we achieve shortened

commissioning and production startup periods,

leading to cost savings.